Warehouse Overstocking: Unpacking the Operational Nightmares and Strategic Solutions

Warehouse Overstocking Operational Challenges

Overstocking: A Deep Dive into Its Impact on Warehouse Operations

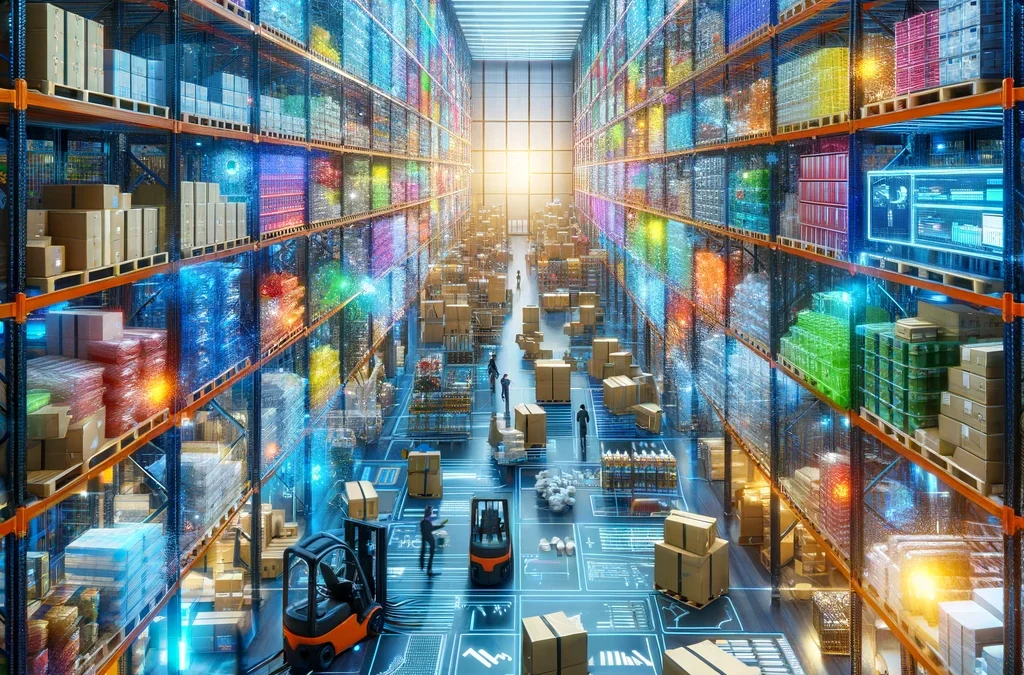

Overstocking, a common pitfall in warehouse management, presents significant operational challenges. When inventory exceeds the storage capacity or demand, it not only congests the warehouse space but also escalates operational costs and complicates logistics. Understanding the nuances of these challenges is essential for developing effective strategies to mitigate them.

The Downward Spiral: How Overstocking Affects Operations

Overstocking a warehouse is akin to clogging the arteries of your supply chain; it restricts the flow of goods and efficiency. Here’s how:

- Increased Operational Costs: Excess inventory leads to higher storage costs. Additionally, the cost of managing surplus items, including maintenance, security, and insurance, adds up, thereby inflating the overall operational budget.

- Compromised Efficiency and Productivity: With aisles filled beyond capacity, the ease of accessing products diminishes. This leads to longer retrieval times, delayed shipments, and ultimately, a decrease in employee productivity.

- Enhanced Risk of Inventory Obsolescence and Damage: Products that sit unsold risk becoming obsolete or exceeding their shelf life. Furthermore, overstocked environments increase the likelihood of inventory damage, leading to financial losses.

Resolving Overstock Challenges Using Warehouse Management Systems (WMS)

A robust Warehouse Management System (WMS) is crucial in mitigating the adverse effects of overstocking. Here’s how it can help:

- Optimized Inventory Management: WMS provides real-time data on inventory levels, helping managers make informed purchasing decisions. By analyzing sales trends and inventory turnover rates, a WMS can prevent the accumulation of excess stock.

- Improved Warehouse Layout and Organization: The system can suggest optimal storage locations and rearrange inventory based on frequency of access and size dimensions, thus maximizing space utilization.

- Enhanced Forecasting and Demand Planning: WMS tools incorporate sophisticated algorithms that predict future demand based on historical data. This predictive capability can significantly reduce the risk of overstocking.

Strategies to Minimize Over-Purchasing and Its Effects

Implementing strategic measures is key to combating the challenges posed by overstocking:

- Adopt Just-In-Time Inventory: This strategy aligns inventory orders with production schedules and sales forecasts, thereby reducing unnecessary stock.

- Regular Review and Adjustment of Inventory Levels: Conducting regular audits and adjusting stock levels based on current market trends and consumer demand can prevent overstocking.

- Supplier Relationship Management: Developing strong relationships with suppliers can lead to more flexible purchasing agreements, such as the ability to return unsold inventory without significant financial penalties.

Transforming Challenges into Opportunities: Employee Training and Involvement

Involving employees in the solution process not only mitigates the frustration caused by overstocking but also turns operational challenges into improvement opportunities:

- Regular Training on WMS Utilization: Ensuring that all staff are proficient in using the WMS can lead to smoother operations and quicker adaptation to system updates and optimizations.

- Feedback Systems for Continuous Improvement: Establishing a feedback loop where employees can report issues and suggest improvements fosters a proactive workplace culture.

Conclusion: Embracing Efficiency and Innovation

Overstocking is more than just an operational nuisance; it’s a significant barrier to efficiency and profitability. By leveraging advanced WMS features and implementing strategic inventory management practices, warehouses can overcome these challenges. This proactive approach not only reduces operational costs but also enhances employee satisfaction and productivity, ultimately leading to a more resilient and competitive business

P4 Warehouse

P4 Warehouse: The Ultimate Cloud-Based Warehouse Management Solution

Experience unmatched efficiency and control with P4 Warehouse, a leading cloud-based Warehouse Management System (WMS) designed to streamline your operations. Tailored for businesses of all sizes, P4 Warehouse offers real-time inventory visibility, advanced automation, and seamless integration capabilities. Enhance your logistical operations with our intuitive interface that simplifies complex warehousing tasks, from inbound processing to inventory control and order fulfillment.

Key Features:

- Real-Time Inventory Management: Gain instant access to accurate stock levels and location data, enabling better decision-making and reduced inventory costs.

- Automated Workflow Optimization: Leverage powerful automation tools to enhance efficiency, minimize errors, and increase productivity across all your warehousing processes.

- Scalable Infrastructure: Whether you’re a small business or a large enterprise, P4 Warehouse scales with your needs, ensuring optimal performance and flexibility.

- Seamless Integrations: Easily integrate with existing ERP systems, eCommerce platforms, and shipping providers to create a cohesive supply chain ecosystem.

Discover how P4 Warehouse can transform your warehouse operations by visiting P4 Warehouse.